Some of the main contributions of our research group to the academic field of textiles and fiber science include the:

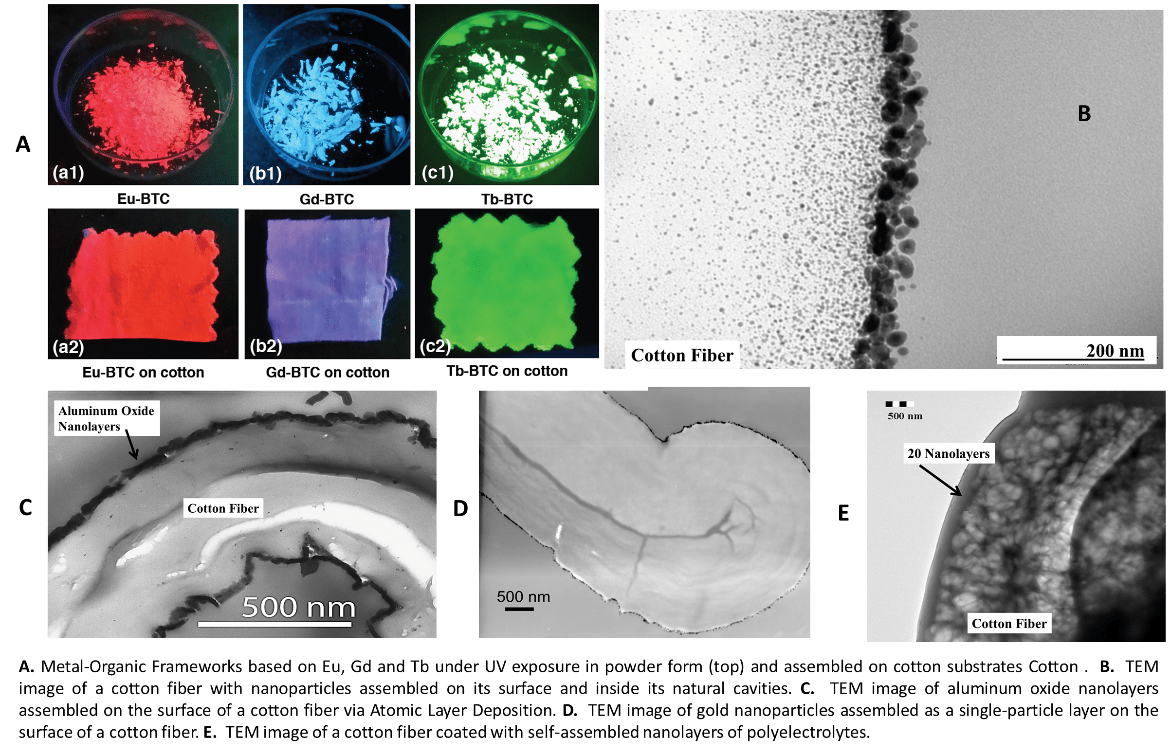

- Discovery of a method to manipulate the assembly of nanoparticles on heterogenous surfaces to create conformal coatings on cotton fibers. US Patent 8,679,197 B2, US Patent 8,491,668 B2, ACS Appl. Mater. Interfaces (2009) (4), 797-803

- Being the first ones to demonstrate layer-by-layer deposition of polyelectrolytes on irregular surfaces such as those of cotton fibers Nanotechnology (2005) 16 S422-S428

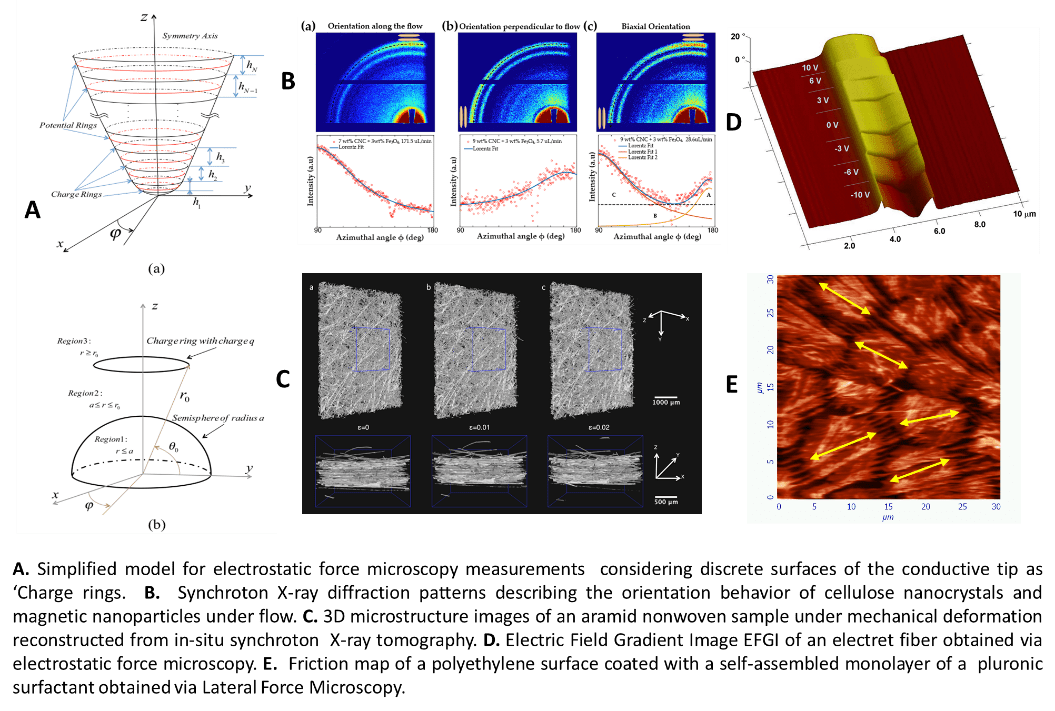

- Pioneering the use of electrostatic force microscopy to probe and quantify electrical charges on polymer electret fibers, and elucidating the mechanisms for dissipation of these charges in fibrous filtration media. Journal of Microscopy 2007, 20,

- Inventing a process, based on Focused Ion Beam selective etching, to manufacture polymer monoliths for precision filtration. US Patent 9,494,865 B2

- Discovery of a synthesis pathway for the seed and growth of metal-organic frameworks on the surface of cotton and synthetic fibers. US Patent 9,186,651 B2 ,

- Development of a synthesis method to grow nanowires on the surface of cotton fibers and the use of nanowires’ composition as positive identification markers for anticounterfeiting applications. US Patent 10,495,624 B2 , ACS Applied Materials and Interfaces 2014, 6, 4, 2262-2269

- Elucidation of lubrication mechanisms in textile fibers and soft surfaces using lateral force microscopy techniques. ACS Appl. Mater. Interfaces, 2011

- Pioneering the use of synchrotron x-ray scattering to probe the structure of cellulose nanocrystals under dynamic conditions such as shear and flow deformation using custom-made apparatuses. Langmuir 2018, 34, 18, 5263–5272

- Invention of a method to deposit polymeric cyclodextrin coatings on cotton fibers to selectively capture micropollutants in air and water. US Patent 10,086,360 B2, US Patent 9, 855,545 B2 , US Patent 9, 624,314 B2, Chemistry of Materials, 2016, 28 (22), 8340-8346

Developing advanced metrology tools of relevance to fiber science: After writing sections of a large grant proposal for an advanced manufacturing institute and interviewing several fiber and textile companies, I confirmed previous observations that the lack of advanced metrology, customized to the unique characteristics of fibrous materials, remains one of the major obstacles for the further advancement of fiber and textile science. For example, the issues of electrostatics and friction phenomena in textile fibers remain major obstacles to fiber manufacturing processes. While over many centuries, some solutions have been implemented, a comprehensive understanding of these phenomena remains elusive –mainly due to the lack of proper metrology tools.

Our group has made seminal contributions in this area. For example, we were the first to report on the use of Electrostatic Force Microscopy to characterize, in a qualitative manner, the charging and discharging of polymer electrets (polymeric fibers with electrostatic charges used in filtration). We expanded the capabilities of those initial measurements by creating mathematical models capable of quantifying the magnitude of the charges, and we presented the first evidence that electrical charges on fibers were not uniformly distributed, as it was assumed for many years. In the area of lubrication and friction, our group developed new techniques using Lateral Force Microscopy to map the location and configuration of lubricants additives on the surface of textile substrates, presenting evidence that the molecular configuration of the lubricant on the surface greatly influences their performance. Our group continues to expand the capabilities of scanning probe microscopy techniques, such as Acoustic Force Microscopy AFAM and Infrared Spectroscopy IR-AFM to get a better glimpse at these old problems as we believe that a deeper understanding of friction and lubrication in textiles can significantly improve the productivity of the fiber and textile industries.

We have used Cornell’s X-ray Synchroton facilities to probe the internal structure of nonwoven substrates via dynamic x-ray tomography and to probe and understand the behavior of cellulose nanocrystals, using customized apparatus, under dynamic conditions. Cellulose crystals have been extensively studied under static conditions using a myriad of electronic microscopy and spectroscopic techniques. Our group unveiled the unique assembly behavior of these materials under shear and capillary flow.

Creating new functionalities on cellulosic surfaces: We are one of the few research groups in the world, using cotton as a primary substrate to create new functionalities. Cotton is a very challenging material with unique physical and chemical heterogeneities –heterogeneities that are amplified as cotton fibers are transformed into yarns and then amplified even more when these yarns become textile structures. Our research group was the first to report on the functionalization of cotton fibers and fabrics with Metal-Organic Frameworks (MOF) using a two step-approach that include the seeding of the metal clusters and the building of the entire framework afterwards. We were also the first to evaluate the potential use of these new textile substrates as sorbents for pesticides as well as antibacterial substrates. We further expanded our work by using lantanide-based MOF structures to change the color of cotton from its traditional white to red, green, and blue (RGB) colors under exposure to UV. Lately, we ventured into post-modification strategies of MOF structures to expand the color palette of these materials under visible light, creating true panchromatic MOFs.

Cotton functionalization strategies previously developed by our group have allowed for the use of other nanoscale moieties as a means to give cotton new functionalities without compromising its comfort properties. We have expanded our portfolio by functionalizing cotton fibers and fabrics with metal nanoparticles, nanolayers of polymers and metal oxides, quantum wires, and superabsorbent polymers. In our latest efforts, we moved from considering cotton as a passive substrate and started considering the chemical functionality of cotton in the synthesis of nanomaterials. This shift in thinking enabled the discovery of new coatings for other fibrous substrates as well as new ways to manipulate cellulosic materials. For example, we created SERS (Surface Enhance Raman Spectroscopy) substrates using nanoparticles on wood dust for applications in food packaging, synthesized nanoparticles on natural fibers such as fique for applications in water purification, used natural extracts of fruits as reducing agents for the synthesis of nanoparticles on natural fibers such as silk and agave, and engineered a new process for molding cellulose-based gels using ionic liquids.

Our ultimate goal is to impart unique properties to natural fibers without affecting their comfort and textile properties. We believe that natural fibers will remain a large section of the textile market for years to come and that enabling them with unique properties is a viable avenue for creating revolutionary textile materials without significantly altering existing textile manufacturing processes.

Our research group has also participated in collaborative international projects focused on creating functional nanofibers, developing strategies to convert nanofibers into textile yarns and coatings, and synthesizing nanomaterials using non-traditional substrates. These projects have allowed us to expand our capabilities beyond our core expertise, expose our students to international and multidisciplinary working environments, learn new analytical techniques and explore new scientific approaches to understand fundamental phenomena of relevance to fiber science.

Nurturing future research talent: None of our research achievements would have been possible without the great and hard work of our research students and postdoctoral associates. As a research advisor of masters and doctoral students I emphasize in my advisees the need to change roles from being consumers of knowledge to becoming producers of knowledge. The most important question my graduate students need to answer in each report or presentation is: why? Answering the “why?” question is not a trivial effort as it requires a dramatic restructuring of their thinking. The process of finding an answer to “why?” opens their minds, allows them to become more analytical and to enjoy their discoveries even more. When graduate students join our lab, we provide them with rigorous training on analytical techniques required for their specific projects, and as time progresses, it is expected that they will become fully independent and evolve into world-class researchers. I see my graduate students as future colleagues, I treat them with great respect, and I promote their work every time I can as I believe that my success as a scholar is proportional to the success of my advisees. Some of our former members have joined academic institutions such as Colorado State University, Seoul National University, Nanjing University, Yale University, Northwestern University, Loughborough University, École Polytechnique Fédérale de Lausanne –EPFL, as well as major corporations such as L’Oreal, 3M, IBM, Nestlé, Dassault Systemes, United Technologies, Sandia National Laboratories, Intel, and HP.

Our international visibility in the field of fiber and textile science has attracted Fulbright scholars from Romania, Czech Republic, Brazil and Colombia. We have also welcomed visiting professors from Hong Kong Polytechnic University, University of Bologna in Italy, University of Buenos Aires in Argentina, Federal University of Santa Catarina in Brazil, Universidad de los Andes in Colombia, Universidad de Cartagena, Kyoto Institute of Technology in Japan, Deakin University in Australia, Jiangnan University in China, and Seoul National University in Korea. Furthermore, world leading textile research institutions such as the Taiwan Textile Research Institute, and the largest fiber manufacturing company, Toray Industries, have sent researchers to work in our laboratory on specific projects and for extended periods of time, under the Cornell Industry Partnership Program of the Cornell Center for Materials Research. I have been invited to present our research work at major events organized by the American Chemical Society, the Materials Research Society, The Fiber Society as well as at universities and research institutions in more than 43 countries.

Finally, mentoring and advising undergraduate researchers is one of my passions. I consider undergraduate research to be one of the most impactful ways of teaching as that experience builds confidence and allow students to explore science as a potential pathway for future professional development. Since my arrival at Cornell I have mentored over 45 undergraduate students from the colleges of Human Ecology, Engineering, Arts and Sciences, Agriculture and Life Sciences as well as REU students from other US universities. Several of my advisees have gone to top graduate, law, medical schools, major US corporations. Some of them have won awards for their outstanding research work and have become co-authors in some of our publications. My philosophy with undergraduate researchers is to present them with a challenging but well-defined problem for which they will be fully responsible for, not merely a sub-problem of a graduate or of a postdoctoral researcher –because I believe that this sense of ownership motivates them to excel and eventually become independent researchers.